Predictive maintenance software

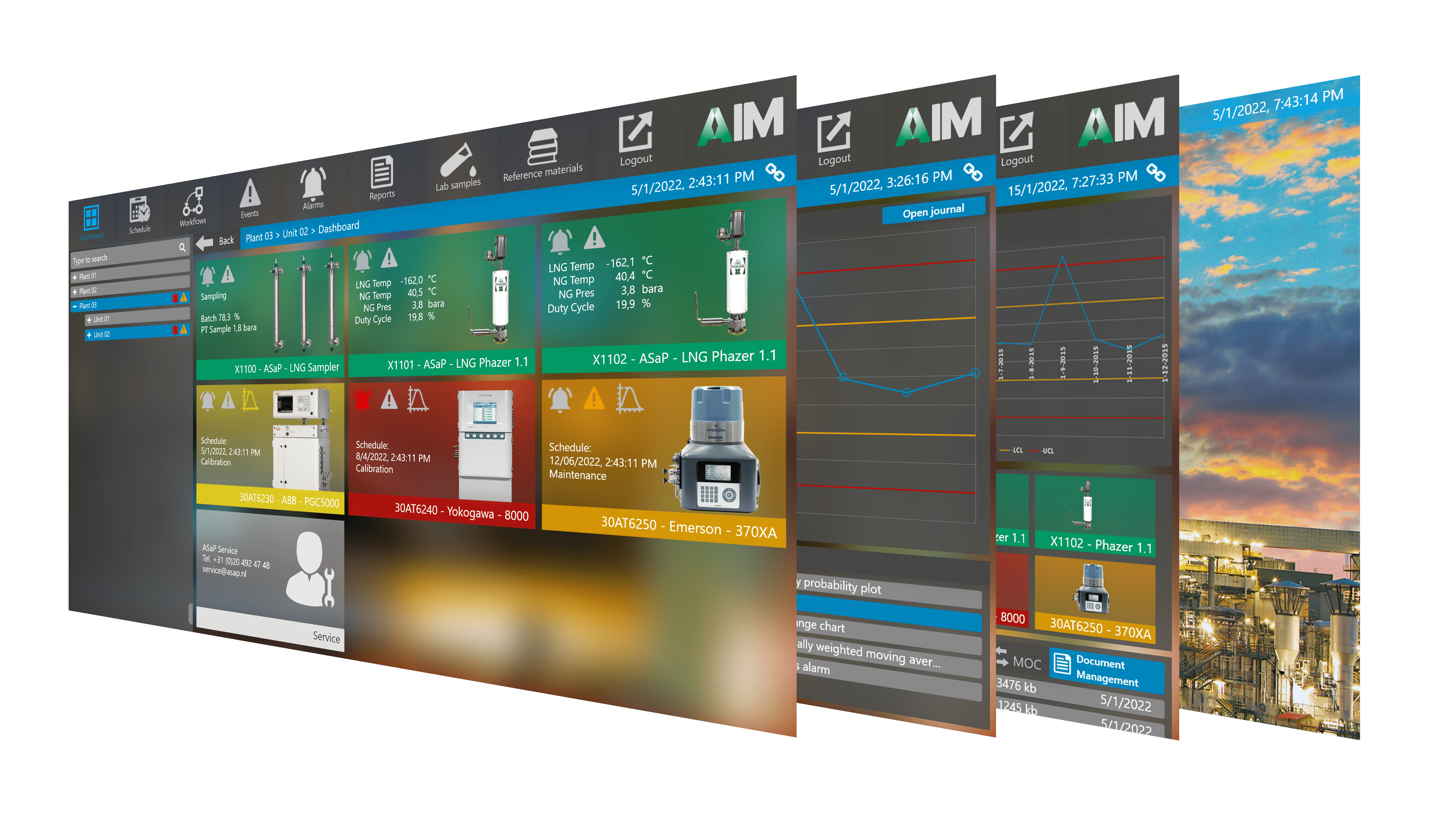

AIM is easy-to-use predictive maintenance software for operators, reliability engineers, and maintenance managers, developed by the engineers of Analytical Solutions and Products.

- AIM monitors your analyzers performance.

- AIM can predict the exact moment to replace your maintenance sensitive parts.

- AIM can validate your analytical equipment from a single location.

- AIM comes pre-configured for your analytical equipment.

- AIM supports virtually support any number of devices.

Our comprehensive range of products includes offshore and onshore service, an extensive selection of gas analysis instruments, sample conditioning, and various cabinets and houses for your instruments, tailored to meet the unique requirements of various petrochemical and cryogenic applications. We are dedicated to delivering innovative solutions that ensure accurate and efficient operations in the process industry.

Table of contents

- Are your analytical instruments giving you reliable, accurate and repeatable results?

- How can the AIM predictive maintenance software algorithms help you and your maintenance team?

- Which KPI’s can AIM predictive maintenance software make visible for you?

- What reports can I expect with AIM predictive maintenance software?

- How is the AIM-architecture designed?

- What are the applications for predictive maintenance software?

- Does AIM comply to the international standards?

- Which other features can you expect in AIM?

- Does the predictive maintenance software AIM support your LNG samplers and vaporizers?

- Need help choosing your next Predictive maintenance software solution?

- Improve your maintenance team and AIM for your success

What is AIM?

AIM is easy-to-use predictive maintenance software for operators, reliability engineers, and maintenance managers, developed by the engineers of Analytical Solutions and Products.

Like AMADAS, AIM collects data from your analytical instruments, and centralizes control over your equipment.

AIM is developed to be a future proof high-tech direction for maintenance control, though still being a low-cost solution in comparison to other systems.

AIM yields high gains in efficiency, predictive maintenance savings and increased availability.

Predictive

AIM is an essential predictive maintenance tool for your reliability engineers.

Control

AIM can control and validate your analytical equipment from a single location, regardless of make and model.

Overview

AIM will bring you complete overview, with KPI’s, clear dashboards, live tiles, and in-depth reports.

Easy

AIM comes pre-configured for your analytical equipment and is easy to implement within your own IT-environment.

Grow

AIM is built to scale, it can virtually support any number of devices. From a maintenance workshop to a complete production plant.

Are your analytical instruments giving you reliable, accurate and repeatable results?

You need to know the level of performance of your analyzer systems; are they giving you reliable, accurate and repeatable results? If not, operation of your analyzer systems could be compromised!

That is why ASaP has developed the Analysis Information Module (AIM). AIM is the only predictive maintenance software with support for all brands of process analyzers used in the oil and gas and (petro)chemical industries.

AIM will bring you complete analyzer data overview, with clear dashboards, live tiles, and in-depth reports. Easily track your workflows, analytical instruments, their measurements, their associated equipment, schedules, and documentation.

How can the AIM predictive maintenance software algorithms help you and your maintenance team?

With key predictive maintenance algorithms and analyzer data acquisition system, AIM is able to provide operators, reliability engineers, and maintenance managers with detailed information and analyses on their analyzer systems so they can monitor and improve process control.

Through monitoring the performance of your analytical equipment, AIM can predict the exact moment to replace your maintenance sensitive parts. You will spot potential problems from miles away. By replacing parts on performance basis, rather than on time-based Intervals, you will make the most of your maintenance budget and see return on your investment.

The AIM predictive maintenance algorithms are designed to determine the condition of analytical equipment in order to estimate when maintenance should be planned and performed. This way promises cost savings over time-based preventive maintenance, because maintenance is performed only when necessary. It is regarded as condition-based maintenance carried out as suggested by estimations of the degradation state of analytical equipment, such as gas analyzers.

Together with your maintenance team you will make better informed decisions and improve your maintenance performance.

Which KPI’s can AIM predictive maintenance software make visible for you?

AIM monitors analyzer performance and provides a clear visualization of the data on Key Performance Indicators (KPI’s) like:

- Performance: accuracy and repeatability

- Maintenance: corrective and preventive

- Availability: actual and historical data

- Validation: (manual/automatic) with statistical evaluation of results

- Calibration: info on gases and consumption

- Monitoring of equipment; ranging from simple transmitters to complex analyzers (GC’s)

What reports can I expect with AIM predictive maintenance software?

AIM features a fully integrated report generator to automate generation of common reports like alarm, state machine, I-chart, and QAL3 reports. You will be able to make the best decision with your analyzer data acquisition system ready to show to anyone.

How is the AIM-architecture designed?

AIM is built on modern technology that allows de-central deployment. And with scalability in mind, AIM is designed so it can virtually support any number of devices. From a maintenance workshop to a complete production plant. It uses standard protocols to allow easy integration. AIM is developed with its own protocol stack and allows integration with common industry protocols such as Modbus TCP/IP, Modbus RTU, Analog and Discrete Signals and OPC.

AIM comes pre-configured for your analytical equipment and is easy to implement within your own IT-environment.

No infrastructure available and still want to implement a predictive maintenance software and data acquisition system? AIM is an independent stand-alone system, which can be integrated at any time!

What are the applications for predictive maintenance software?

AIM is designed for oil and gas and (petro)chemical industries. But since AIM’s design is based on common industry protocols and works with any analytical device regardless of brand or model, AIM’s applications for AIM are endless. These applications are just a few amongst many. Because of AIM growing number of users these applications will be updated regularly.

-

The ASaP team

The ASaP engineering team Analytical Solutions and Products B.V. boasts an engineering team comprised of innovative left-brain thinkers who excel in logic and holistic problem-solving. This talented group is at the core of ASaP’s ability to design and develop a wide array of cutting-edge products, including advanced probes, comprehensive sample systems, and sophisticated electrical and…

-

Sample probes for extracting representative samples

Challenges with gas sampling and sample probes In the process industry, accurate sample extraction is paramount. However, professionals face three major challenges: Our sample probes, tackle these challenges head-on. They ensure the extraction of a true representative portion, filter out contaminants, and optimize sample efficiency. Step into a world of precision with ASaP’s sample probes.…

-

Process gas chromatograph analyzers – How to choose a PGC?

In this article about process gas chromatographs What is Gas Chromatography (GC) in short? In short Gas Chromatography (GC) is an analysis technique which is able to separate hundreds of different components while determining the composition qualitatively and quantitively. The principles of gas chromatography make a powerful tool to specifically analyze one or more gases.…

-

Sampling systems for gas analyzers and process conditions control

The challenges with Sample Handling Systems (SHS) Most process problems come from the design of the sample conditioning. The better understanding of both process and gas analyzer is critical in the design and fabrication of the sample conditioning systems. In the demanding world of the process industry, professionals grapple with several challenges: With our in-depth…

Does AIM comply to the international standards?

Yes. AIM complies to international standards. Amongst others the STM D-6299 standard. The ASTM D-6299 norm is a standard practice for applying statistical quality assurance and control charting techniques to evaluate analytical measurement system performance. AIM predictive maintenance software covers information for the design and operation of a program to monitor and control ongoing stability and precision and bias performance of selected analytical measurement systems using a collection of generally accepted statistical quality control (SQC) procedures and tools.

Which other features can you expect in AIM?

- Scheduler, Schedule tasks (such as validations) from a single platform

- Document Store – Documents (drawings, manuals, certificates etc.) can be stored for each device, have everything at hand from a single location!

- Cylinder management, management of certificates, composition, expiry dates for all validation materials.

- User management

- Time synchronization

- Discovery of AIM devices and service

- Gas detection

- Sample systems

- LNG phase diagram

Are you missing a feature that has not been listed? Please contact our specialist to see what we can do for you.

Does the predictive maintenance software AIM support your LNG samplers and vaporizers?

Yes. We have integrated full LNG sampler and vaporizer functionality within AIM predictive maintenance software. Operators can control the LNG sampler with one interface and have an overview of all information such as LNG vaporizer, LNG sampler, and gas analyzer performance. AIM has been developed in-house by the ASaP engineering team and can be implemented with any brand or type of LNG sampler, LNG vaporizer, and gas analyzer available in any system, new or retrofit!

Need help choosing your next Predictive maintenance software solution?

Contact our predictive maintenance software specialist directly

You can contact us is you have a question about predictive maintenance software when it suits you. See our specialist’s contact information below.

🔧

📨

📞

🔗

Let our predictive maintenance software specialist contact you

Let us know how we can reach you to discuss predictive maintenance software. We will only use this information for contacting you.

Contact form

Improve your maintenance team and AIM for your success

predictive maintenance software practical solutions

With predictive maintenance software ASaP offers practical total solutions. The well-established and complementary ASaP analytical package of services and products is an important contribution to the right solutions for your analytical needs. Moreover, the team spirit and the cooperation with specific partners give us the opportunity to design, build, locally install and commission tailor made sample probes, analyzer systems and shelters for you. All these products and systems can be built according to the latest industry guidelines and certifications.

ASaP is the reputable provider of analytical solutions; We can provide you with a full-service package for including engineering, manufacturing, software development, offshore service, gas analyzers, system integration, and cutting-edge bio-LNG or LNG Custody Transfer Systems (CTMS), LNG Probe-Vaporizers, advanced LNG Sampling Systems, and precise natural gas analysis systems. You are kindly invited to consult our team about predictive maintenance software or any analytical challenge!

1 thought on “Predictive maintenance software & data acquisition system – AIM”

Comments are closed.